Over a year of

Professional Research Experience

B.Sc. in Bioengineering

From Northeastern University

I am a bioengineering graduate from Northeastern University, with a concentration in Biomedical Devices and Bioimaging. My goal is to develop life-changing devices to improve the efficiency and quality of patient care. In the coming years, I want to improve to broaden my experience in the bioengineering field and improve the engineering skills I'll be using for the rest of my career.

Piscataway, NJ

Feb. 2025 - Present

In my current role, I continue to use my wet lab skills by venturing into mass spectrometry. Under the guidance of Dr. Haiyan Zheng, I work on projects from across Rutgers' greater research community, including other labs from Rutgers itself, labs from universities across the country, and even some nearby corporations. Using advanced LCMS systems such as the QE Exactive HF, Orbitrap Eclipse, and Bruker timsTOF, we conduct a variety experiments from hydrogen deuterium exchange analysis to molecular weight calculation.

Burlington, MA

Jan. 2023 - June 2023

In my second co-op, I joined the lab of Dan Wilson as part of the hydrogels project. I worked on the development of new hydrogel formulations, including experimenting with different polymers, crosslinkers, dyes, and pigments. In conjunction with Northeastern's Deravi and Joshi labs, our goal was to develop a gel which could consistently and reversibly change size and color depending on the acidity of the surrounding buffer. You can read more about this project below!

Charlestown, MA

Jan. 2022 - June 2022

In my first co-op, I joined Solid's Process Development team. With the goal of developing a viral vector gene therapy for Duchenne Muscular Dystrophy, I contributed to the team's HSV and AAV production experiments. My responsibilities included maintaining multiple mammalian cell lines with HEK-293 or Vero-27 type cells, conducting experiments to optimize virus production and adherent cell attahcment to microcarriers, and managing bioreactor environments using DeltaV bioreactor software.

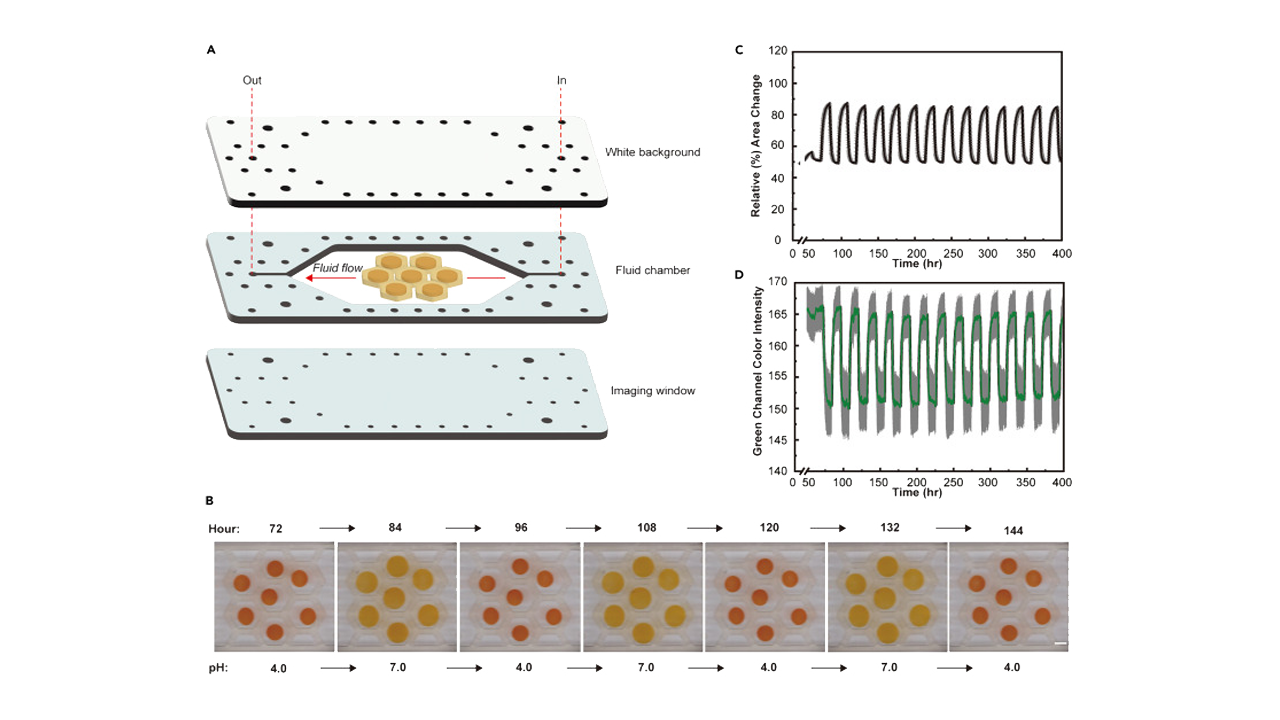

Check out the publication of this project in

Matter!

The publication has more information on the entire project, but my

contributions are shown on the right. Using a laser cutter, I

constructed a buffer-exchange chamber out of layers of silicone

rubber and acrylic. Inside, a 3D printed holder kept hydrogel

pucks in place while images were taken over a two week period.

Using ImageJ, I quantified the size and color changing

capabilities of a specially designed poly(acrylamide-co-acrylic

acid) gel.

Skills:

Wet Lab, OnShape, ImageJ, Soldering, Experimental Analysis

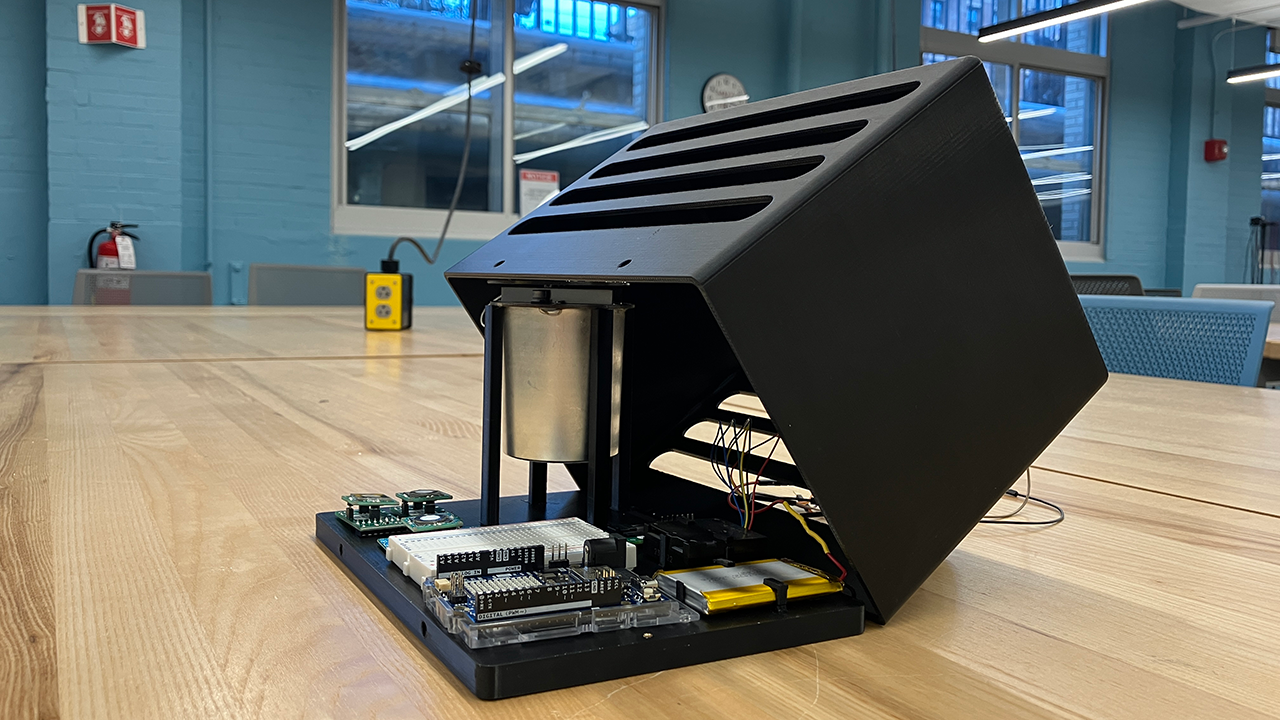

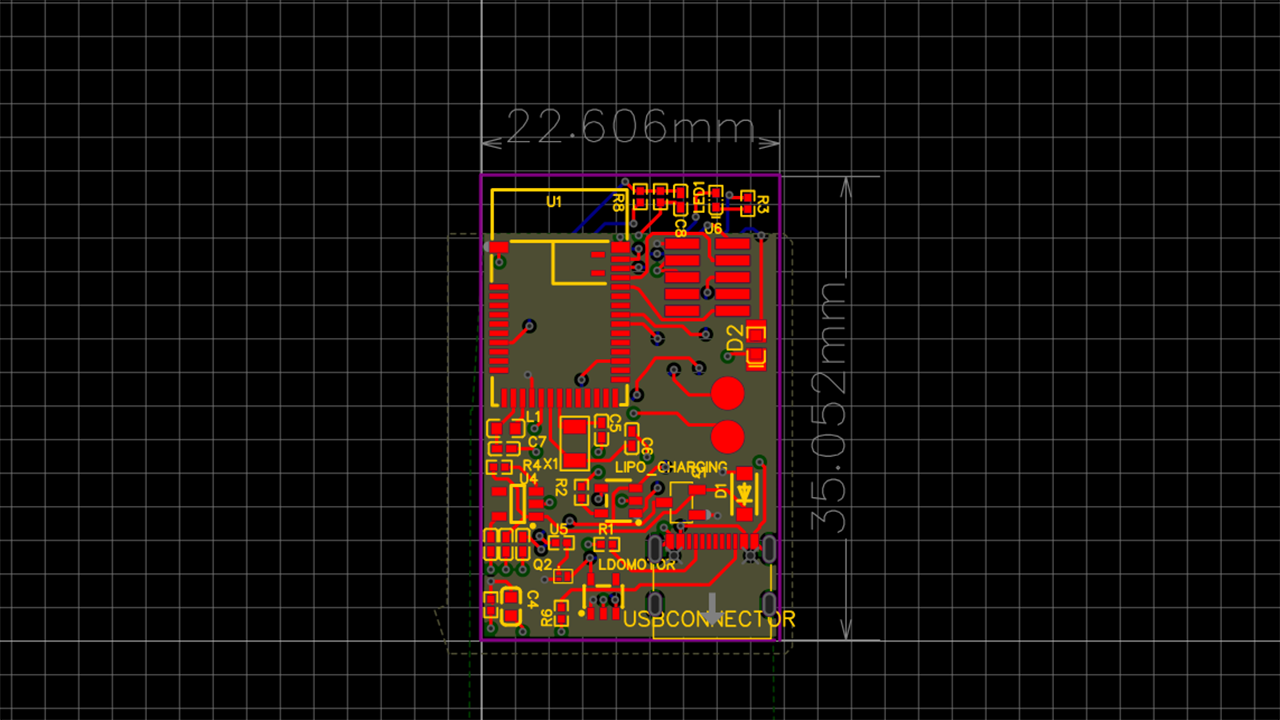

Many houses in rural Knox County Maine are susceptible to indoor

air pollution from wood or gas burning. However, data

characterizing pollutants and linking that to respiratory

conditions is scarce. Our goal was to construct a device which

could sense a greater range of pollutants than commercially

available devices while transmitting air quality data to a server

over WiFi for a year-long period. We eventually brought the device

to a Knox County Town Hall prior to our final presentation and

poster demonstration at Northeastern.

Skills:

KiCad, SOLIDWORKS, Soldering, C++

Read about this project in

Northeastern News!

As part of Northeastern's Generate Product Development Studio, we

were tasked by Tatum Robotics to develop a bracelet and doorbell

combination for the Deaf-Blind community. Currenlty, they lack a

good way to know when someone is at their door, leading them to

often leave their door unlocked. Our bracelet/doorbell combo

communicated over bluetooth and vibrated when someone rang the

doorbell.

Skills:

PCB Design and Assembly, EasyEDA, Soldering, C++

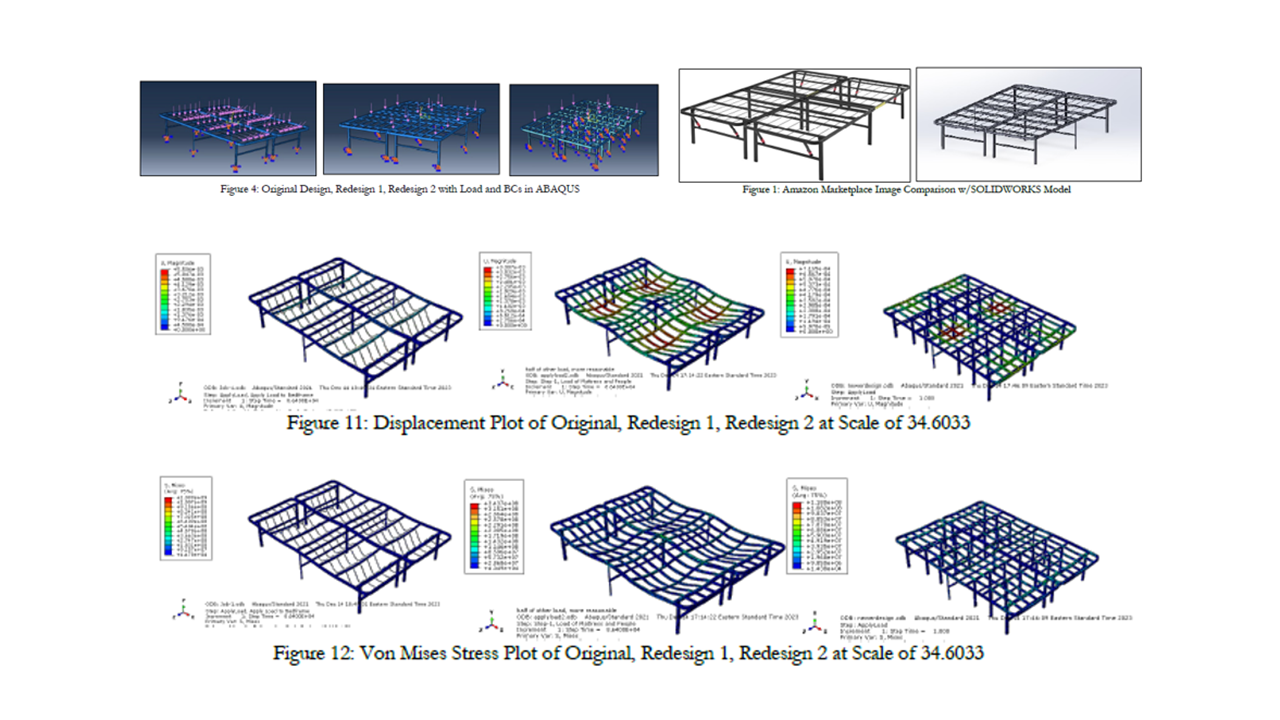

As part of Northeastern's Mechanical Engineering Computation and

Design course, my final project tasked me with taking an object in

my daily life and redesigning it. As someone with a cheap creaky

bedframe, I naturally chose this as my object. I produced two

redesigns with extra supports in SOLIDWORKS while maintaining the

symmetrical design to maintain the bedframe's foldability. After

simulating loading using Abaqus FEA software, I demonstrated that

my redesigns expereinced less deformation under a high load.

Skills:

Abaqus FEA, SOLIDWORKS, Report Writing

In another semester at Generate's Product Development Studio, I

worked on a kitchen appliance specifically designed for the

West-African cuisine, Fufu. Our kitchen-aid style mixer integrated

mixing, induction heating, and water dispensing systems to allow

for an automated Fufu cooking experience. As part of the

electrical team, I aided with designing the water dispensing

sytem, writing code for the machine, and integrating the PCB.

Skills:

KiCad, VSCode, C++, Git

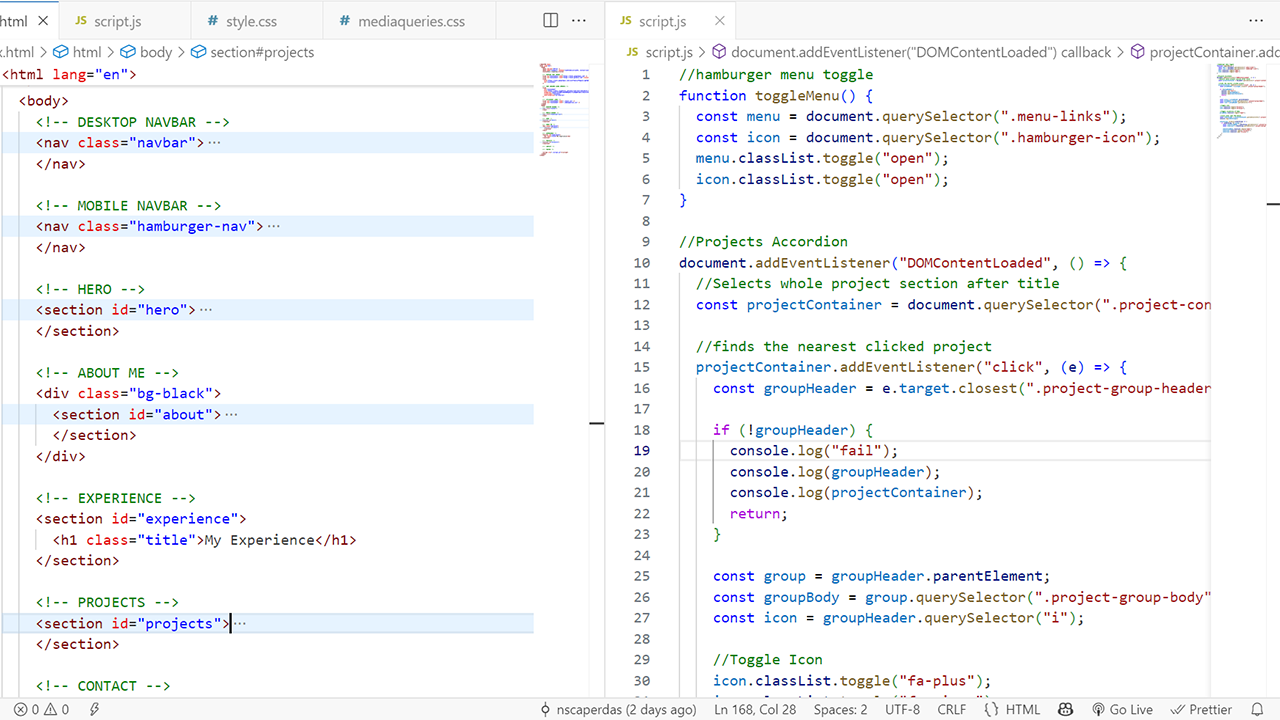

In school, I pursued a computer science minor to support my

engineering career. To sharpen my coding skills following school,

I taught myself HTML and CSS using online resources. After uniting

some skills learned from various online tutorials, I brought

together my learned skills to showcase my experience in this

website! I hope you have enjoyed the final product!

Skills:

HTML, CSS, JavaScript, VSCode, Git